Key Highlights

Here are the main things to know when you pick and use a welding blanket:

- A welding blanket keeps you safe from fire by blocking sparks and molten metal.

- Heat resistance is the key feature you will need because this blanket must hold up to the high temperatures during your welding project.

- There are different materials to pick from, like fiberglass, and they each give you different levels of protection and strength.

- You have to use the welding blanket correctly and put it in the right spot for better safety on the job.

- You should check and take care of your welding blanket often. This way, you know it’s ready if there is an emergency.

- Picking the right size makes sure you get all the coverage you need for your welding project.

Introduction

In welding, there are many risks, so safety must come first. The welding process has dangers, like sparks and molten metal. These can start small fires at any time. That is why you need fire blankets. They are important safety products. Fire blankets help to put out small fires fast. They also protect people and surfaces in the work area. Picking the right fire blanket helps everyone feel more safe and have peace of mind. This keeps your work space safe and secure.

Understanding Fire Blankets for Welding Safety

A welding blanket is not just any cloth. It is made to keep you safe from the fire hazards that come with welding. A standard blanket cannot take the same kind of heat. A welding blanket is built to stand up to the high heat and sparks that you get from welding. This makes it an important tool on the job.

Knowing your equipment is the first step when you want to use the right safety measures. This guide helps you understand why fire blankets are important. It also looks at their key features and shows how they are not the same as regular fire blankets.

What Makes Welding Fire Blankets Essential?

Any welding project, whether big or small, brings fire hazards. You will see that hot sparks can fly. Molten metal may spatter to nearby surfaces and cause fire risk. A welding fire blanket is important safety equipment. It helps protect people, tools, and what you own from these fire hazards.

These blankets are made to stand up to the extreme temperatures that happen during welding. You can use one to put out a small fire before it gets out of hand. You can also cover things with the blanket to keep them safe from fire from the start. Their use is important in keeping the workspace safe.

Materials like fiberglass are used a lot because they have good heat resistance and last a long time. They are safe to use and work well when you need to do welding. It is important to use the right blanket before you start any welding job. This step should not be skipped.

Key Differences Between Welding and Regular Fire Blankets

It is easy to think all fire blankets work the same, but this is not true. Fire blankets can have different purposes. A regular fire blanket is used at home, like putting out a small kitchen fire caused by grease. It is not made for the tough, ongoing heat found in industrial applications such as welding. For welding, you need fire blankets that can handle much higher heat.

Welding blankets are strong flame retardant covers. They be made to handle sparks, spatter, and high temperatures. These covers help protect you from fire hazards and the potential fire hazards you may face in welding areas.

The main difference is about how well they can handle heat and what they are made of. Here’s a quick look at both:

| Feature | Regular Fire Blanket | Welding Fire Blanket |

|---|---|---|

| Intended Use | Small household fires (e.g., kitchen) | Industrial settings, welding, high-heat work |

| Heat Resistance | Lower; suitable for smothering flames | Very high; withstands sparks and molten metal |

| Material | Often wool or standard fiberglass | Heavy-duty fiberglass, silicone-coated, carbon fiber |

| Durability | Designed for one-time use | Often reusable and built for rough environments |

Important Features to Look For in a Welding Fire Blanket

When you want to pick a welding fire blanket, you need to know what to look for. Some blankets give better protection than others. It is important to check key features so that you get one that works the way you need. Not every blanket is the same, so take time to find one that will help keep you safe.

Each part of a welding blanket matters, like the material durability, the heat resistance, size, and safety standards. All these work together to make the blanket work well. We will go over what gives a welding blanket its value. You will read about the material options, fire ratings, and how to pick the right size for what you need.

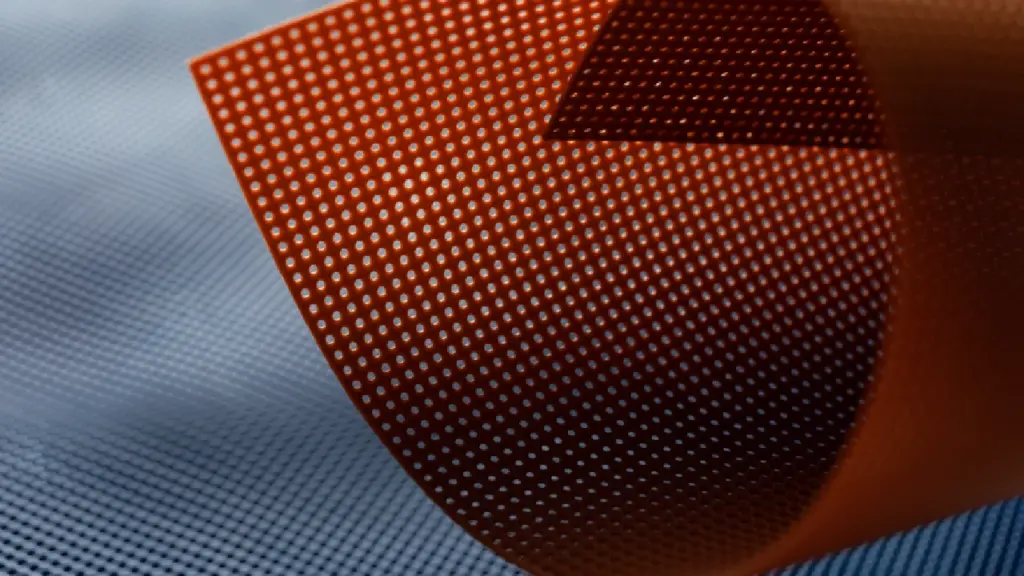

Material Considerations: Fiberglass, Silica, and More

The material of your fire blanket matters when you work on your welding project. Each type can give you a different level of heat resistance. Material durability is key, too. The blanket needs to last and stay strong when you use it. A flame retardant material is a must. It helps keep you safe and should be part of all fire blankets for welding.

When you need a fire blanket for welding, there are some things to look for. The most important is the material. Some types of material are better for this job and get used most often. These materials work well and help keep you safe.

- Fiberglass: This is a common pick because it has good heat resistance and is tough. It works well for many welding jobs, so you can trust it most of the time.

- Silicone-Coated Fiberglass: This kind gives you better protection from wearing out and from some chemicals. Because of this, it is stronger and lasts longer.

- Carbon Fiber: Carbon fiber is known for exceptional heat resistance and strength. It is right for the most intense welding situations. You can use it when you need extra protection.

Choosing a good material like silica yarn or strong fiberglass makes sure your blanket can take the heat. It will give you the protection you need.

Heat Resistance and Fire Ratings Explained

A welding blanket must be able to stand up to high heat. This is the most important thing to look for in a welding blanket. A blanket with high heat resistance gives you unmatched protection from sparks, flames, and molten metal. You should always check the temperature rating to be sure it is higher than the heat you expect to have at work.

Fire blankets come with temperature ratings. They are also grouped by the types of fires they can put out. This helps you know which one is best for your workspace. Some fire blankets work on Class A fires. These fires start with things like paper, wood, or cloth. Other fire blankets work on Class B fires. These fires start with flammable liquids. Use these fire ratings to find the right blanket for what you need.

For keeping surfaces safe when you weld, the best fire blanket is made from strong materials. A good choice is silicone-coated fiberglass. This type can handle high heat. It will not break down when it gets hit by spatter. It gives you a barrier you can trust.

Choosing the Right Size for Your Application

Size is important when you need good fire protection. If the blanket is too small, it will not cover the work area or the fire. This can make you, or the people in your shop, be at risk. Fire blankets come in various sizes. You can get small ones for quick jobs or big ones for bigger spaces, like factories or shops. So, there is something for any need.

Think about the welding environment you have. Ask if you are going to work on a small part. Or do you need to cover a big machine or wall? Picking the right size is important so you get full coverage. For projects you do most often, keep these points in mind:

- If you need to do small or tabletop welding, a standard 40″ x 40″ blanket will often be enough for the job.

- When you are working in bigger areas or need vertical protection, it is better to use a much bigger blanket. A larger blanket will help cover the walls and equipment better.

Some suppliers offer custom sizes to help you get the right fit for your workspace. You need to measure the area you want to cover. Pick a blanket that gives enough overlap, so you can be sure about safety.

Best Practices for Using Fire Blankets During Welding

Having the right welding blanket is important. But, knowing how to use it the right way is also needed. When you use the welding blanket properly, you can act fast if there is an emergency. This helps to make a secure working environment for all people who are there.

By using the right safety measures during installation and setup, you can stop a small problem from turning into something much bigger. Let’s talk about the best ways to put and use your fire blanket so you get the most out of its protection.

Proper Installation and Secure Placement Techniques

For a fire blanket to work well, it needs to be easy to reach. Quick access is very important when there is an emergency. You should make sure it is put up the right way and that it stays in a safe spot. You do not want to look for the blanket when there is no time to waste. Every second matters.

The main goal is ease of deployment. The blanket needs to be kept in a spot where anyone can get it and use it. People should not need a lot of training. Think about these tips for where to put it:

- Put the blanket on the wall where it is easy to see and get to.

- Keep it near doors and in places where fire is likely, like the main welding area.

- Use special hooks or holders that keep the blanket safe but make it quick to take out.

Make sure you keep and store your welding fire blanket the right way. This helps you use it fast when you really need it. It makes everything safer and saves time in an emergency.

Surface Protection and Coverage Tips

One main use for a welding blanket is to keep surfaces safe. It works as a heat shield and stops sparks or molten metal from hurting floors, walls, or equipment. If you want to keep good workplace safety, you have to use the welding blanket the right way.

When you set up your workspace, put the blanket on top of any areas that need to be kept safe. Make sure the blanket is big enough to cover the space without leaving any open spots. If there is a fire, you can use the blanket to put it out by covering the flames.

- Gently put the blanket over the flames, making sure it covers all of the fire.

- Press down hard so that the oxygen supply gets cut off.

- Keep the blanket there until the area feels cool so the fire does not start up again.

A strong blanket that can handle high heat is the best choice to protect surfaces. It can take direct spatter from the work and still not break or get damaged.

Maintenance and Longevity of Welding Fire Blankets

A welding fire blanket is something you use to protect yourself over a long time. To make sure it keeps you safe, you need to practice regular maintenance. You should take care of it often, so the blanket works well when there is an emergency. The blanket can get worn out from heat and regular use. If you look after it, you can help stop damage from building up over the year.

If you keep up a regular routine for cleaning, storage, and inspection, your blanket will last longer and help with fire safety. Be sure to know the signs of wear and see when the blanket needs to be swapped out for a new one.

How to Clean and Store Your Fire Blanket

To take care of your fire blanket, you need to clean it and store it the right way. Dirt and other stuff can make the blanket less safe, so you want to keep it clean. Always read what the maker says about cleaning. The blanket, its material, and the brand may have rules you need to follow.

After you clean your blanket, the next step to keep material durability is storage. A blanket that is stored in the right way will last and be ready to use. Keep these tips in mind for the best results:

- Keep the blanket in a clean and dry spot.

- Do not put it near heat sources or chemicals, as they can harm the material.

- Fold it the way the maker says, so you can use it right away when you need it.

Taking these simple steps gives you peace of mind. You will know that your safety equipment is in good shape and ready to use.

Inspection, Repair, and Replacement Guidelines

Regular maintenance means you need to take a close look at your fire blanket from time to time. You have to check it often for any signs of damage. The main thing is to make sure there is nothing wrong with it that could hurt its strength or stop it from meeting safety standards. Look for anything that would make the blanket unsafe to use.

Watch out for some signs of damage. These can include:

- Tears, holes, or frayed edges may show up.

- Discolor, burn marks, or stains could be there.

- A melting, breakdown, or wearing away of the layer might happen.

If you see any damage that you can not fix, you need to replace the blanket right away. Some fire blankets are made for just one use, mostly after you put out a fire. Even if you do not see any damage, you should think about getting a new blanket every so often. It is best to follow what the maker says, so your fire blankets work well when you need them.

Top Brands and Where to Buy Quality Welding Fire Blankets

Choosing a trusted brand is important when you buy safety products like a welding fire blanket. Good makers follow strict quality rules. They also make sure their products pass EN ISO tests or offer FM approved choices.

With the many options out in stores and on the web, it can feel tough to know the best place to begin. We will go over some brands that people suggest and give tips about how to buy the right one. This will help you pick out a good blanket that you can count on.

Recommended Brands and FM Approved Options

Finding the best fire blanket begins when you pick a trusted brand. A good brand is one many people know for being reliable and making quality safety equipment. Brands like Mart Cobra and Fire Blanket Safety focus on products for industrial applications. Professionals in the field often suggest these brands when you want the best fire blanket.

These brands make products that follow strong safety standards. They want you to feel sure about what you buy. When you shop, check if the product clearly says FM Approved. This means it has been tested well to see how it works and if it is safe.

Here’s a look at what some recommended brands have to offer:

| Brand | Key Features | Best For |

|---|---|---|

| Mart Cobra | Professional-grade welding blankets, high-temperature resistance, durable construction for heavy-duty use. | Industrial and construction settings with high-risk operations. |

| Fire Blanket Safety | Premium materials like fiberglass, various sizes for comprehensive protection, emphasis on ease of deployment. | General welding environments needing reliable and easy-to-use blankets. |

You can buy FM approved welding fire blankets from the websites of these brands. You can also get them from industrial safety suppliers who focus on these products.

Tips for Purchasing Online and In-Store

Whether you choose to shop online or in-store, there are tips that can help you get the right safety equipment. A site like Amazon has many choices. It’s important that you buy from trusted sellers so you do not end up with fake safety equipment.

If you want to be sure about what you get, go straight to the brand’s website, like Mart Cobra. You can also shop at a shop that sells only industrial supplies. When you decide what to buy, remember these things:

- Make sure the blanket fits safety rules and matches your unique needs.

- Check what other people say. Read customer reviews to see how the product works in real life.

- Look at features. Compare things like the material, heat rating, and size so you know if it’s good for your job.

When you take some time to look up information, you can pick what is right for you at work. It helps you feel safe in your workplace. You also get a tool you can trust to help protect you from fire.

Conclusion

To sum up, having a good welding fire blanket is important for safety when you work on welding projects. Knowing what makes welding fire blankets different from others, and learning about proper use and taking care of them, can help lower the chance of problems. It is important to use the right materials, get the right size, and pick trusted brands when you look for the best fire blanket. This keeps you and others safe at work. Safety always comes first. If you want help picking the fire blankets that fit your needs or if you have any questions, feel free to ask for advice. Your safety is important to us.

Frequently Asked Questions

Are fiberglass fire blankets safe and effective for welding?

Yes, fiberglass fire blankets are a good choice for welding. The material fiberglass works well in these safety products. It has strong heat resistance and stands up to high temperatures. A fiberglass welding blanket helps keep you safe. It protects you from sparks and spatter during welding. You can count on this fire blanket for good fire safety.

Can I use a welding fire blanket outdoors safely?

Yes, a welding fire blanket is made to stand up to extreme temperatures. You can use it outdoors, even when things are not sure or the weather changes. Safety measures need to be in place outside too. A blanket helps stop damage from sparks and high temperatures when you weld. Always tie it down well, so wind does not blow it away.

How do I properly maintain a welding fire blanket?

You need to check your fire blanket often for any signs of wear. Look for things like tears or burns on it. Be sure to clean it like the maker says. Keep it in a place that is clean, dry, and easy to get to. By doing this regular maintenance, you make sure the fire blanket is always ready for proper use when there is an emergency.