Welding & Hot-Work Safety

Protect people, equipment, and surfaces from sparks, spatter, and high heat. InsoFire provides certified fire-resistant fabrics and blankets that create safe, compliant hot-work zones on shop floors and job sites.

Understanding the Risks

Hot-work processes such as welding, grinding, and cutting generate sparks and molten metal that can ignite nearby materials. Heat transfer can damage paint, cables, glass, and sensitive components, leading to rework or costly downtime. Proper fire barriers are essential to keep the workspace safe and compliant.

Our Solutions

We deliver high-performance shielding materials tailored for hot-work safety. From flexible blankets to coated fabrics, our products block sparks, absorb spatter, and resist extreme temperatures.

Primary Spark Shields

Welding Fire Blankets – Versatile and durable, these blankets can be used as vertical curtains or horizontal floor drapes to catch sparks and molten metal around welding zones.

High-Temperature Zones

Silica Cloth – Designed for direct exposure to high heat, ideal near arcs, torches, and furnaces. Handles continuous temperatures up to 1000 °C, short-term peaks to 1500 °C.

Rugged Surface Protection

Vermiculite-Coated Fiberglass Fabric – For repeated contact with hot debris; resists abrasion and offers thermal protection up to 810 °C continuous, 1090 °C peak.

Clean Handling & Water Resistance

PU-Coated Fiberglass Fabric – Combines spark resistance with anti-fray edges and water repellency, suitable for outdoor or damp environments.

Recommended Products

Welding Fire Blanket

Essential for curtains and floor shielding.

Silica Cloth

For extreme heat areas and torch operations.

Vermiculite-Coated Fiberglass Fabric

Heavy-duty protection against hot debris.

PU-Coated Fiberglass Fabric

Water-repellent and fray-resistant spark shield.

Deployment Examples

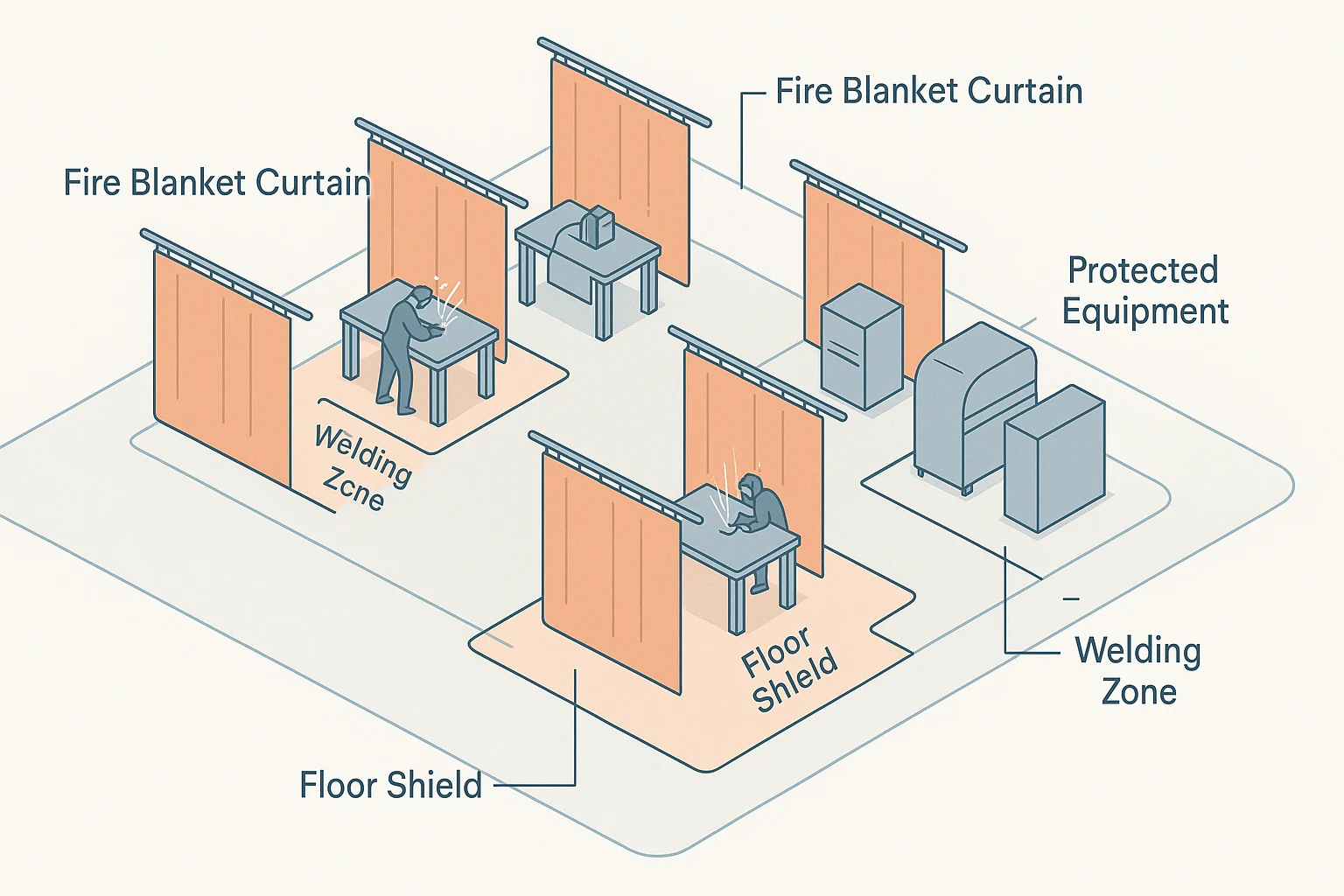

Example layout of a welding safety zone with fire blankets, floor shields, and protected equipment.

For maximum protection, hang overlapping curtains around the work zone, place floor drapes extending 60–90 cm beyond the area, and wrap sensitive equipment with coated fabric panels.

FAQs

Which fabric should be closest to the heat source?

Use Silica Cloth directly near the arc or torch, backed by Welding Fire Blankets and Vermiculite-Coated Fiberglass for surrounding zones.

Can these blankets be used outdoors?

Yes. PU-Coated Fiberglass Fabric is designed to resist moisture and maintain edge stability outdoors.

Are the blankets reusable?

Yes, they can be reused multiple times when inspected for damage after each operation.

Take Action

Build a compliant hot-work safety zone for your facility. Contact us to specify the right combination of blankets and fabrics for your tasks.