Marine & Shipbuilding Heat & Fire Protection

Engine rooms, decks, and refit areas demand durable materials that handle heat, vibration, and moisture. InsoFire provides flexible fabrics and blankets that protect crews, components, and structures during operation, maintenance, and repair.

Where the Risks Come From

Propulsion systems, exhaust manifolds, and hot surfaces generate intense radiant heat. Refit and hot-work add sparks and spatter. Salt, oil, and constant movement accelerate wear on ordinary covers and shields.

Our Marine-Focused Solutions

We combine high-temperature resistance with robust handling to suit shipyards, engine rooms, and deck operations. Choose reflective wraps for radiant heat, fire blankets for hot-work, and coated fiberglass for weatherable covers.

Radiant Heat Barriers

Aluminized Fiberglass Fabric — Reflects radiant heat around exhausts, turbo housings, and heat exchangers. Cut-and-fit panels for pipework, housings, and bulkhead shields.

Hot-Work Containment

Welding Fire Blankets — Hang as curtains or lay as drapes during dockside or onboard welding, cutting, and grinding to catch sparks and molten metal.

Weatherable Protective Covers

PU-Coated Fiberglass Fabric — Moisture-resistant, clean to handle, suitable for temporary jackets, valve covers, and equipment tarps above and below deck.

Featured Products

Welding Fire Blanket

Ideal for protecting surfaces from sparks and molten metal.

PU-Coated Fiberglass Fabric

Water-resistant fabric for covering equipment and creating partitions.

Aluminized Fiberglass Fabric

Radiant heat shielding for sensitive areas near hot work zones.

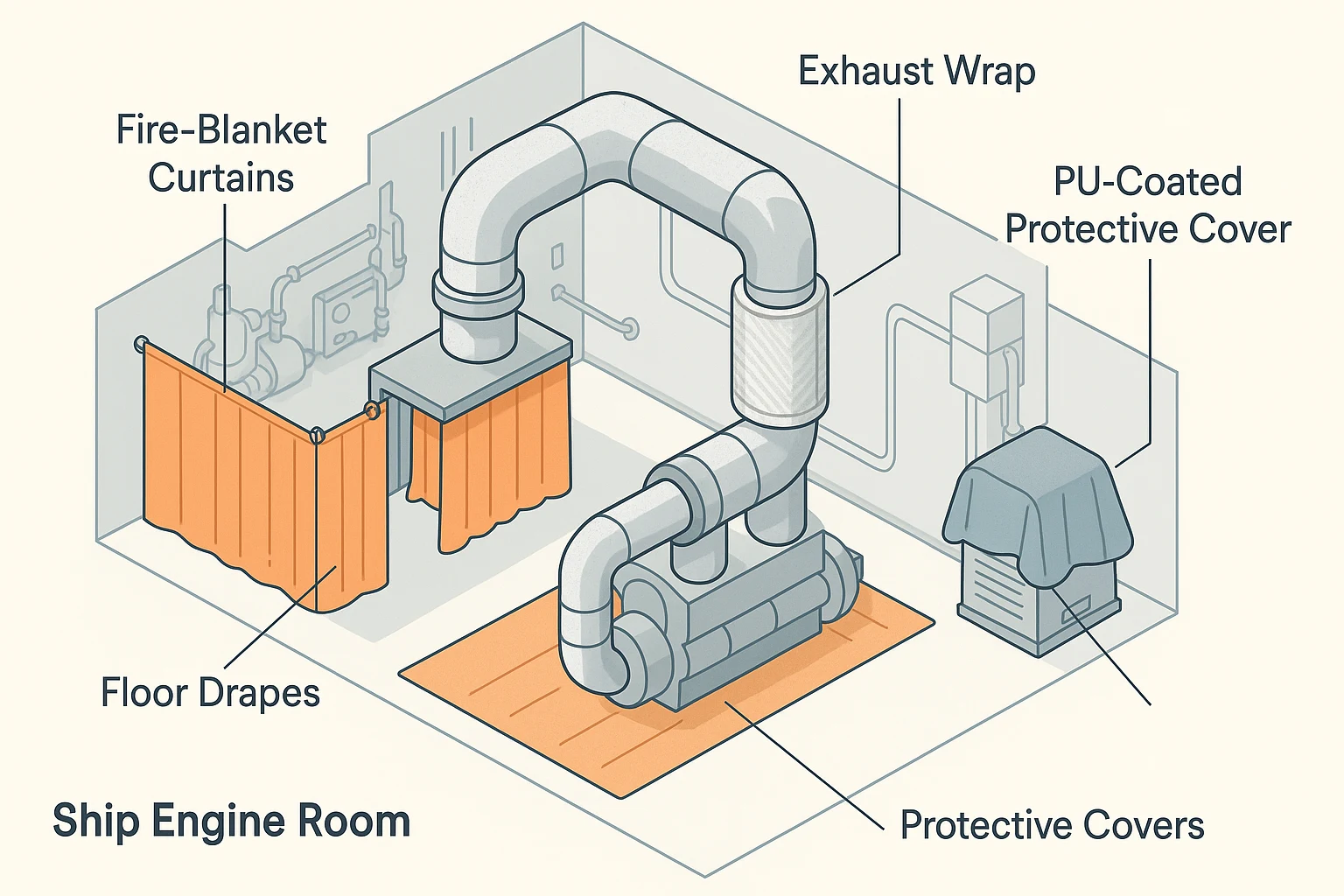

Deployment Examples

Wrap exhaust runs with pre-cut aluminized panels, leaving inspection windows where needed. During refit, hang overlapping fire-blanket curtains around the work zone and extend floor drapes 60–90 cm. Use PU-coated covers to protect sensors, cabling, and paintwork from spray and grime.

Maintenance Tips

Inspect seams and fasteners after every voyage. Replace pieces showing delamination or burn-through. Keep blanket cabinets dry and accessible on deck and near engine-room entries.

FAQs

Can the reflective fabric handle vibration and salt exposure?

Yes. It is designed for flexible wraps and shields in marine environments. Periodic inspection ensures long service life.

What should be closest to the heat source?

Use Aluminized Fiberglass for radiant reflection at hot surfaces, supported by Welding Fire Blankets to contain sparks during hot-work.

Are the covers reusable?

They are reusable when intact. Clean with mild agents, dry thoroughly, and store away from direct UV when off-duty.

Take Action

Specify marine-grade wraps and hot-work protection for your vessel or yard. Contact us to build a tailored kit for your operations.