Key Highlights

- Glass fiber is made from very fine strands of glass and is well-known for its strong mechanical properties.

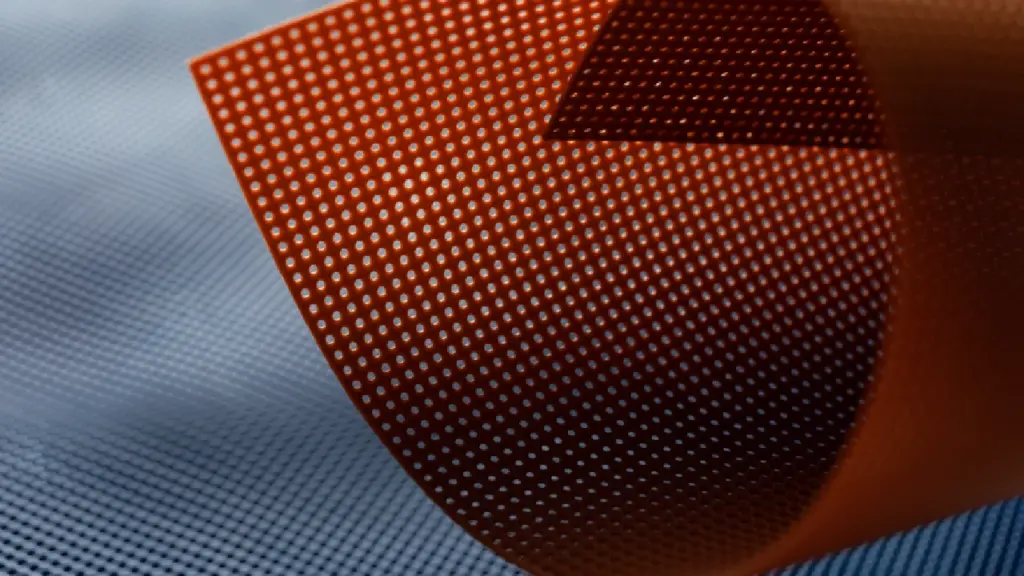

- To make glass fiber, several types of glass get melted down and then pushed through tiny holes. This makes the glass turn into thin strings called filaments.

- The main features are its high tensile strength, good chemical resistance, and how well it works as thermal and electrical insulation.

- There are different types of glass fibers, like E-glass and S-glass, and each type is best for certain uses.

- People use glass fiber in many ways. It is used for building insulation, car parts, parts for planes, and also in boats and ships.

Introduction

Have you ever thought about what makes boats and building insulation both strong and light? A lot of the time, the answer is glass fiber. This material comes from different types of glass. People use it a lot in reinforced plastic. Glass fiber can be woven into fabric or used in mats. With it, workers make composite materials that many of us use every day. Knowing what glass fiber is and how it works shows why it has become so important in building things and in factories.

Overview of Glass Fiber

Glass fiber is a non-metal object made from many very fine fibers of glass. To make glass fiber, people melt different types of glass. Then, they pull the melted glass into thin strands. These thin strands have very good mechanical properties.

When you mix these fibers with a resin, you get a composite material. It is tough and light at the same time. This makes it the right pick for many different uses. Let’s look at what a composite material really means and see the way it is not the same as “fiberglass.”

Definition and Composition

Glass fiber is made by pushing hot, melted glass into very thin strands. The main ingredient is silicon dioxide, also called silica. Silica is a type of polymer. It usually needs very high temperatures to melt and work with. So, to make things easier, other materials are put in. These help lower the melting point of the molten glass.

These fine fibers go through several steps for different uses. You can weave them into a fabric. You can also spread them out in a random mat. Another way is to chop them into short pieces.

When glass fibers mix with a resin matrix, they form a composite material called reinforced plastic. This is also known as glass-reinforced plastic (GRP) or fiber-reinforced plastic (FRP). The composite material takes the strength from the glass and sticks it all together with the plastic. The plastic helps hold everything in place. The end result is a strong and flexible product that can be used in many ways.

Differences Between Glass Fiber and Fiberglass

Many people use “glass fiber” and “fiberglass” to mean the same thing, but there is a difference. Glass fiber is just the thin strands of glass. These strands of glass are what give the material its main mechanical properties.

The word “fiberglass” usually means the finished composite material. This happens when glass fibers are mixed with a resin matrix. The mix creates reinforced plastic known as fiberglass-reinforced plastic (FRP).

Glass fiber is the main part that goes into making fiberglass. Fiberglass is the finished mix. You can think of glass fiber as the rebar found inside, while fiberglass is like the full piece of strong concrete. The two are linked, but glass fiber is just one of the things that make up fiberglass.

Historical Development of Glass Fiber

The idea to make fibers from glass has been around for many years. Glassmakers have tried doing this for centuries. But it was not until new technology came that making a lot of it at once became possible. A big change happened in 1893. A dress made from glass fibers that felt like silk was shown in the United States.

Fiberglass, as we know it today, was first made in the 1930s. Games Slayter came up with it to be used as thermal building insulation. This was a big change. It made new ways for people to make things and new uses possible. Let’s see the key milestones and technical advancements that came after.

Early Discoveries and Milestones

People started to learn about making glass fiber because they were curious and wanted to try new things. A long time ago, craftspeople in Egypt and Venice found ways to pull glass into thin fibers. But it was not until late in the 1800s that many people noticed glass fiber. At the 1893 World’s Columbian Exposition, a dress made from glass fiber was shown. This event helped people see that glass fiber could be used for more than just decoration.

The big change happened in 1932 to 1933. Games Slayter from Owens-Illinois made “glass wool” to help keep buildings warm. People still use this product today. This new idea was the start of the modern fiberglass industry.

In 1938, Owens-Illinois and Corning Glass Works started working together. They made a company called Owens-Corning Fiberglas Corporation. This partnership helped improve the first glass formulation meant for glass fiber with continuous filaments. It also helped show how glass fiber can be used for many things. People found out that it had good mechanical properties and a friendly toxicological profile.

Evolution in Manufacturing Techniques

The way the industry changed how to make things was important for glass fiber to be sold to customers. At first, working with pure silica was really hard. Pure silica does not have a true melting point, so you must use very high temperatures before you can make it soft. That means the costs go up, and it’s not easy to make a lot of glass fiber at once.

To fix this, the makers started putting impurities, called “fluxing agents,” into the molten glass. These extra things help bring down the necessary work temperature. This makes it easier to make glass and helps the process go faster. Because of this, different types of glass came out, each one with its own special features.

A big step forward was when continuous filament formation started. Owens-Corning made this possible. This way, people could create long and unbroken strands of glass fiber. These filaments could then be woven or chopped. This helped make many different products with a resin matrix. The process gave new ways to use glass fiber and strands of glass in several things.

Types of Glass Fiber

Not all glass fiber is the same. The different types of glass have their own chemical formulas, which gives each type special features. There are types of glass fibers like alkali glass that give good chemical resistance, and electrical glass that works well for insulation. The way each glass fiber is made can change how it works. This means that engineers and designers can pick the best types of glass for each job they have.

The most common types of glass fiber are E-glass, S-glass, and C-glass. There are some other types of glass fiber too. Knowing what sets these types apart helps you pick the best one. You might want the best strength, good durability, or strong corrosion resistance. The right choice depends on what you need for your work.

E-glass: Electrical and Structural Applications

E-glass, also called electrical glass, is the most common type of glass fiber in the world. This type of glass fiber got its name because it was first made to help with electrical insulation. E-glass is an alumino-borosilicate glass with less than 1% alkali oxides in it. That makes it a poor conductor of electricity. Because of that, people use it a lot in printed circuit boards and many types of electrical appliances.

Besides its electrical qualities, E-glass also has good tensile strength. It does not cost much to make. Because of this, people often pick it as the main material for general-purpose reinforced plastic, or GRP uses.

It has some good properties, like low dielectric permeability. This makes it a good pick for lots of things, like boat hulls and car parts. But, it can get hurt by chloride ion attack. So, it is a poor choice for some marine uses. In these cases, other types of glass may work better.

S-glass: High Strength Applications

When you need a type of glass fiber that gives the best strength and performance, S-glass is the right choice. The “S” in its name means “Strength.” This glass fiber is made from alumino-silicate and has a lot of magnesium oxide in it. It also has much higher tensile strength and modulus than E-glass.

These better mechanical properties make S-glass a key composite material in areas where things just can’t break or stop working. You will see it in aerospace parts, airplane building, and also in top military and defense uses.

On top of being strong, S-glass also does well when there are high temperatures. It keeps holding together and stays tough even when things get really hot. This makes it good for situations that need more from the material. S-glass costs more than E-glass, but it works so well that many people feel it is worth spending the extra money when the job is tough. In Europe, people call a similar type of glass R-glass, which stands for “reinforcement.”

C-glass, A-glass, and Specialty Fibers

Other than E-glass and S-glass, there are some types of glass fibers made for special uses. C-glass is one of these, and the “C” means chemical resistance. This glass is made with alkali-lime and has a lot of boron oxide in it. The main reason to use C-glass is for its strong chemical resistance. It does a good job protecting against chemical attack, so people often use it to line storage tanks and pipes that handle chemicals.

A-glass, also known as alkali glass, was the first kind of glass that people used for fiberglass. This glass is made from soda-lime and is simpler to make. But, it does not have the same level of chemical resistance as some other glass types. Now, A-glass is mostly used in things where resistance to water or chemicals is not very important.

Other specialty glass fiber types are ECR-glass and D-glass. ECR-glass gives better resistance to acid and alkali. D-glass is known for its low dielectric constant. These different types of glass fiber make sure there is one that works well for many environments or needs.

Core Properties of Glass Fiber

Glass fiber is used in many industries because of what it can do. It is strong like metals, but it does not weigh so much. This makes it easy to use and carry. Glass fiber also does not get damaged by a chemical attack. It gives good thermal insulation, so it keeps heat in or out very well. These things together make glass fiber a strong and lasting material for different jobs.

When you look at the different types of glass fibers used, you can change how this material works to match certain needs. Let’s look at the basic parts, including the way it handles force, heat, chemicals, and electricity. These things help show why the types of glass fibers are so useful.

Mechanical Properties

One good thing about glass fiber is that it has strong mechanical properties. It has a high strength-to-weight ratio. Strands of glass on their own are very strong. When you put strands of glass together and mix them with a resin, you get a very tough material. This material has great tensile strength. Because of this, it can handle a lot of pulling without breaking.

Glass fiber is strong when you compare it to other materials. It has mechanical properties that are similar to polymer fibers. Glass fiber is also not as brittle as carbon fiber. This means it can handle impacts better. The high strength of glass fiber helps it work well in many uses. People use it in building beams and in helmets for protection. It is a good choice because of its reliable and comparable mechanical properties.

While it may not be as hard as carbon fiber, this material offers good strength and can last a long time. It usually costs less, and that makes it a good choice for many uses where tough performance is needed.

Thermal and Chemical Resistance

Glass fiber is known for being very strong in tough conditions. It has great chemical resistance, so it is good to use around corrosive chemicals. Glass fiber does not rust or break down like metals do. That is why you see it a lot in the chemical industry. People use it to make storage tanks, pipes, and filters.

Glass fiber is great at fighting off rust. It also works well to keep heat from passing through. The reason is that it has a low thermal conductivity. This means heat does not move through it quickly. Because of this, glass wool is often used for building insulation. It helps homes stay warm in the winter and cool in the summer.

Certain types of glass fiber—like S-glass—can handle high heat well. These types of glass keep their strength even when it gets hot. This mix of heat and chemical strength helps make glass fiber tough and gives it a long life.

Electrical Insulation Capabilities

Another important thing about glass fiber is that it gives great electrical insulation. Glass does not let electricity pass through it. This helps make it very safe and good to use with electrical parts and wiring. That is why many people pick glass fiber when they want strong electrical insulation.

E-glass, known as electrical glass, was made for this exact purpose. It has a low dielectric constant and low dielectric permeability. This helps keep energy loss low and stops electrical problems. That is why it is used as a base material in printed circuit boards (PCBs) inside many electronic devices.

Glass fiber is used in many electrical appliances that people have at home. It is also important in big machines that work in factories. The material helps to keep things safe and work well by giving good insulation. People can use it the way they want because it can be woven like fabric. This means it fits many shapes and sizes, so it works with different needs.

Glass Fiber vs. Other Fibers

Glass fiber is a popular material for making things stronger, but it is not the only one out there. When you look at glass fiber next to other strong fibers, like carbon fiber and aramid fibers such as Kevlar, you will see some differences. Each of these has its own mix of strength, stiffness, and price. This means they all fit different applications where you need a certain kind of performance.

Glass fiber is a good choice when you want both performance and an affordable cost. This material gives you mechanical properties that are close to what you get from more expensive fibers, but you pay much less. Knowing how these options are different helps you pick the right one for your reinforced plastic project.

Strength Comparison With Carbon and Aramid Fibers

When you talk about pure strength, the fight to be the best is tough. Carbon fiber is well-known for its high tensile strength and amazing stiffness. Because of this, people often use it in high-performance things like race cars and planes. Aramid fibers are strong, too, and are known for handling big impacts and being very tough.

Glass fiber, especially the type called S-glass, is known for its high strength. It may not be as stiff as carbon fiber, but glass fiber is not as brittle. This means it holds up better when hit or damaged. E-glass is another type that gives good strength, and this is enough for many things people use in daily life and for many things in factories. A lot of people and companies pick glass fiber or carbon fiber because they both give high strength.

Here’s a simple way for you to see the difference:

| Fiber Type | Tensile Strength | Stiffness (Modulus) | Key Advantage |

|---|---|---|---|

| E-Glass Fiber | Good | Moderate | Cost-effective, Insulating |

| S-Glass Fiber | Very Good | High | High Strength |

| Carbon Fiber | Excellent | Very High | Stiffness, Lightweight |

| Aramid Fibers | Excellent | Moderate | Impact Resistance, Toughness |

Cost and Performance Analysis

Choosing a reinforcing fiber is usually about finding a balance between cost and how well it works. Carbon fiber is very stiff, and it is lighter than most other options. But it costs much more. This makes it a great choice for things where weight must be as low as possible and when there is a big budget. However, for most everyday building materials, it is not the best choice because of the high price.

This is where glass fiber shows its real value. It gives the composite material strong mechanical properties but does not cost as much as other options. That is why glass fiber is often the first choice in the industry. For many people, the small extra strength you get from carbon fiber does not make up for its much higher price.

This good cost and performance make glass fiber a key material in composites. It gives the strength, long life, and the different uses that makers need for things like car parts and surfboards. At the same time, it helps keep the costs of making those things under control.

The Manufacturing Process of Glass Fiber

Have you ever wondered how these thin but strong glass fibers are made? The way people make glass fiber is very interesting. It mixes the use of chemistry and work done at very high heat. The process starts when the right mix of raw materials is put together. Then, these materials are melted to make molten glass.

This molten glass gets pulled through very tiny bushings. This step forms long, thin filaments. The process needs close control of heat and speed. This is important to get the right size and feel for the fiber. Let’s look at the main steps, starting with raw materials and ending with how the fiber is made.

Raw Materials Used

The main material used to make glass fiber is silica (SiO2). People usually find it as sand. But pure silica has a very high melting point, and that makes it hard to use. So, to lower the melting point and make things easier, manufacturers add other materials called fluxing agents. This helps the process be more efficient.

The kind of glass you get depends on the raw materials you use. The first type of glass that people made was soda-lime glass. People also call this A-glass. It has alkali oxides in it. E-glass does not have alkali in it. Instead, this glass is made with alumino-borosilicates.

The fiberglass industry is the single largest consumer of boron minerals in the world. To make E-glass, they pick the right ingredients. These are mixed to make a batch. This batch will then be melted to form the glass.

Melting and Formation

After the raw materials are mixed, they go into a furnace. Here, they are heated to very high temperatures, close to 1700°C. This heat turns them into molten glass. A thing to know about glass is that it does not have a true melting point like some other materials. Instead, the glass gets soft slowly as the heat goes up. This makes it easy to draw the glass into fibers.

The added fluxing agents bring down the necessary work temperature. This helps make the glass easier to handle. After melting, the molten glass moves into a forehearth. Here, it cools down to the right temperature needed for fiberization.

The glass goes through bushings. The bushings are made from special metals and have many small holes. The molten glass moves down through these holes fast. This pulls and stretches the glass into thin threads, called glass fiber. The speed of cooling and drawing decides how the glass fiber will turn out, like its coefficient of thermal expansion. So, glass fiber properties depend on how quick the molten glass cools and moves, which changes its thermal expansion.

Continuous Filament and Staple Fiber Processes

After coming out from the bushings, the glass fibers can be worked with in a few ways. This helps to make different forms of the material. The two main ways to do this are by making continuous filament or by making staple fiber.

In continuous filament formation, the long and unbroken strands come together and are wound onto spools. These continuous fibers can be used right away for things like filament winding or pultrusion. You can also have the fibers woven into fabrics. If you want, the fibers can be cut into chosen lengths. These cut fibers can then be made into a chopped strand mat or strand mat.

The staple fiber process makes short fibers. People often use these fibers for insulation, like glass wool. The different forms of glass fiber are:

- Continuous Roving: These are bundles of long, untwisted threads. People often use them for spraying or weaving things.

- Chopped Strand Mat: This is made from fibers that point in different ways. A binder holds all the fibers together. Many use chopped strand mat and strand mat to help strengthen other materials.

- Woven Cloth: This is a type of fabric. It is made by weaving yarns that are in one long piece.

- Glass Wool: This is a soft, fluffy material filled with air. People use glass wool for insulation because it can keep out the cold and heat.

Construction Techniques Using Glass Fiber

Having glass fiber is important, but you need to do more to make it a useful product. Several ways can be used to mix glass fiber with a resin. This is how people make a finished composite material. With these methods, you can make things like flat panels or even complex shapes that are strong and solid.

The way you make a part depends on what shape you want, how many you need to make, and how you want it to perform. There are a few methods that people use the most. Some of these are filament winding, hand lay-up, and spray lay-up. Each one has its own good points. Let’s see how these processes work.

Filament Winding

Filament winding is an automatic way to make parts that are hollow, round, or have a curved shape. In this process, long strands of glass fiber pass through a bath filled with resin. Then, these glass strands are wrapped around a spinning mold called a mandrel. You can control the angle at which the glass fiber goes around the mold. This helps make the part stronger in certain directions.

This way of making parts works very well and gives you strong pieces. The fibers in the part are lined up to help take on the force you would expect the part to feel. You get the most out of the high tensile strength because of the long filaments in the material. The part you end up with is tough and holds its shape.

Filament winding is used a lot to make things that need to be strong and keep water or gas from leaking. The method works well for high-pressure pipes and rocket motor casings. People also use it to make large storage tanks. While this way works best if the shape is simple, you can also use it for some complex shapes.

Hand Lay-Up Operation

The hand lay-up operation is a simple and old way to make parts with composite material. In this method, people put layers of glass cloth or mat into a mold by hand. After that, they use a liquid resin matrix to soak these layers well.

Workers use brushes or rollers to push the resin into the fabric. They make sure there are no air bubbles. The team makes sure all of the fabric is covered. More layers get added until it gets to the thickness they want. After this, the part is left to harden. Most of the time, it hardens at room temperature.

The hand lay-up technique takes more time and work than machine methods. But this way of making things is very flexible. People use it to make big and complicated items, like boat hulls. It also works well for custom car bodies. The hand lay-up method is a good choice when you need to make small numbers of large building materials and other special parts.

Spray Lay-Up and Pultrusion Methods

For faster production of parts, the spray lay-up method is often used. With this way, a special spray gun is used. The spray gun chops up long fiber roving into short fibers. At the same time, it mixes them with a resin that has been mixed with a catalyst. The spray then covers the mold. This step keeps building up the thickness you want.

Pultrusion is a way to make strong things like rods, beams, and channels. It is a very automatic and ongoing process. In this method, there are long fibers that get pulled through a bath filled with resin. After this, they go into a heated die. The die shapes the object and makes the resin hard. This is how the final part is made and ready to use.

Both of these ways work better than hand lay-up when you want to make more parts. Spray lay-up is good when you have to make big things with some complex shapes, like shower stalls. Pultrusion is the best way to make a lot of structural building materials.

Common Uses and Applications

Thanks to how useful it is, glass fiber shows up in many different applications. You can find glass fiber in various forms, like woven cloth or chopped mats. When glass fiber is mixed with a resin matrix, it creates glass fiber composites made for specific uses. There is a good chance you use products made from this material every day without knowing it.

From the walls of your home to the car you drive, its effect is seen everywhere. Let’s look at some of the most common ways it is used. We will talk about key fields like construction, automotive, and aerospace.

Building and Construction Industry

The building and construction industry uses a lot of glass fiber. This material is known for helping with thermal insulation. People put products like glass wool batts and rolls in walls, attics, and floors. These help make your home feel just right and can make it use less energy.

Glass fiber is added to many things to make them stronger. You will find it in roofing materials, concrete, and plaster. It helps them last longer and not break easily. Glass-reinforced plastic, or GRP, is made with glass fiber in it. GRP panels can be used when you need cladding, canopies, and other building parts. They are light and also have good corrosion resistance. This means the panels will not wear out fast when the weather is bad.

Some building materials use glass fiber. Here are some common examples:

- Roofing shingles and panels

These are used on the top of the house. They help cover the roof. People put these on their homes, so the rain and sun stay out. The roof looks good and also lasts a long time. - Wall and ceiling insulation

This helps to keep homes warm in winter and cool in summer. It goes in the walls and on the ceiling. People use it to save energy and feel good inside their homes. - Reinforcement for concrete and plaster (GRC)

This makes concrete and plaster stronger. The GRC is mixed to give strength, so things do not crack or break. People use this in many buildings and homes. - Prefabricated bathroom units and shower stalls

These are made before being put in the house. You can get a whole bathroom or shower stall ready to use. It saves time when making or fixing homes. People want these because they are easy and quick to install.

Automotive and Transportation Sector

In the automotive and transportation field, glass fiber has become a key material. There is a big need for lighter and more fuel-efficient vehicles. That is why companies now use glass fiber to make composite material parts. These parts can take the place of heavy steel pieces. They are much lighter, but still have high strength and can take a hit without breaking.

You can see glass fiber composites used in many car parts, like body panels, bumpers, and hoods. People also use this material for things inside cars, such as dashboards and door liners. In trucks and caravans, glass fiber or glass fiber composites may make up whole cabins or other big sections of the body.

The use of glass fiber composites makes it simple to shape parts into complex forms. This helps cars get better designs, which can boost how well they move. These materials are light, strong, and easy to form. All of this shows why glass fiber is so good for new cars in the automotive world.

Marine, Aerospace, and Defense Uses

The marine industry has used glass fiber for a long time to build boats and yachts. This is because it has good chemical resistance to saltwater. It also has a high strength compared to how much it weighs. These features make glass fiber great for making boat hulls and superstructures that last a long time. Glass fiber composites are also used for making spas and swimming pools.

In the aerospace and defense sectors, performance is very important. High-strength S-glass is used when you need parts with great mechanical properties. You will find it in aircraft parts, radomes, and missile coverings. Its high tensile strength helps these items stay strong and work well, even under a lot of stress.

From small boats for fun to high-tech military equipment, glass fiber is used. It gives the right mix of strength, lasting power, and the ability to stand up to lots of weather. This is why many people trust glass fiber for these tough jobs.

Safety and Handling Considerations

Glass fiber is a useful material. But, you have to be careful when you handle it. The tiny fibers can be risky for your health if you do not have the right safety steps in place. Unlike some other dangerous things, glass fiber is not called a cause of cancer. Its toxicological profile is well-known and clear.

Direct contact with glass fiber can make skin feel sore or itchy. It’s important to know what problems may happen and learn the safety steps you need to follow. This knowledge is useful for people working with glass fiber at a factory or at home as part of a project.

Health Risks Associated With Glass Fiber

The main health risk from glass fiber is that it can cause irritation when you touch it. The small, sharp pieces can stick in the top of your skin. This can make the skin feel itchy and give you a rash. Many people call this skin irritation. It is the most common problem people have when they work with glass fiber.

Breathing in fibers in the air can make your nose, throat, and lungs feel sore. You may also start to cough. But, the North American Insulation Manufacturers Association says that these fibers are too big to go deep into your lungs. The body has natural ways to clear them out over time.

Many studies on the toxicological profile of glass fiber show these fibers do not stay in the lungs for a long time. The glass fiber will not cause long-term harm the way asbestos does. If you handle it right, it is not known to be a cause of long-term disease. [Source: https://insulationinstitute.org/wp-content/uploads/2016/02/HSH203.pdf]

Recommended Safety Measures

To lower health risks, it is important to follow safety tips when you handle glass fiber. The most important thing you can do is wear the right protective gear. This means putting on long-sleeved clothes that are loose, gloves for your hands, and safety glasses. These will help keep the glass fiber from touching your skin and getting in your eyes.

To stop breathing in glass fiber dust, you need to work in an area that has good airflow. When you cut, sand, or spray glass fiber, there is often a lot of dust in the air. Make sure you wear a dust mask or a respirator that is made for this kind of work. This is very important.

After you handle the material, wash your hands and any skin that is out in the open. Use soap and cold water for this. It is good to clean up well and store all materials the right way. This will help cut down on glass fiber exposure. If you take these easy steps, you can use glass fiber in a safe and smart way.

Environmental Impact of Glass Fiber Production

The way glass fiber is made can affect the environment. Making glass fiber needs a lot of energy to melt the raw materials. The energy often comes from fossil fuels. Using these fuels adds to problems with greenhouse gas that go into the air. It also needs the use of natural resources.

The industry is working hard to be more sustainable. Many people in it want to recycle more and use less energy. There is also work being done to help lower the effect this has on the earth. Now, let’s look at where recycling stands and talk about other ways this connects to nature.

Recycling and Sustainability Initiatives

Yes, glass fiber can be recycled. But there are some challenges with it. During the process of making glass fiber, extra pieces called cullet glass are left over. These leftover bits can be melted again and put back into making new glass fiber. This way, waste goes down and it also takes less energy to melt the raw materials to make the next batch.

Recycling glass fiber items that people use and throw away is tough. This is because you have to take the fibers out from the resin matrix first. But there are now new ways that people are working on. These ways break down old glass fiber pieces. Then, the ground-up parts can be used in new building materials or in other products.

Sustainability initiatives try to make products better for the environment. One good example of this is glass fiber insulation. It helps lower the energy needed to keep buildings warm or cool. Over time, this gives a good impact on the environment.

Ecological Concerns and Mitigation

The main issues with glass fiber production are how much energy it uses and what gets put into the air. The process needs furnaces that run at very high temperatures. You need a lot of natural gas or electricity to keep them going. This causes the process to use a lot of energy and adds to the problems for the environment.

Manufacturers want to make furnaces work better and use less energy. They are also looking at new sources for power. Some factories now use stronger rules to control smoke and other stuff that gets into the air. A good toxicological profile for the final product means it will not let out any bad substances into the environment when people use it.

The glass fiber industry is also working to be more sustainable. They help by reusing and recycling glass fiber products. This means they take waste and turn it into useful material. When they do this, companies can put less in landfills and save natural resources. This helps lower the lasting impact on the environment.

Conclusion

To sum up, glass fiber is a useful material that can be used in many ways. This is because it has some great features, like being strong, keeping heat out, and giving good electrical insulation. Over the years, glass fiber has changed a lot. New ways to make it have helped people use it in more fields, like building and flying. It is important to know the good things and the safety rules about glass fiber, especially if you work with it. If you know the benefits and use the right safety steps, you will make better choices for your projects. If you have any questions or want advice about using glass fiber, feel free to ask for help or a meeting!

Frequently Asked Questions

What are the main advantages of using glass fiber?

The main advantages of glass fiber are its high strength compared to its weight, strong chemical resistance against rust, and really good thermal and electrical insulation. When you use glass fiber in something like a composite material, it helps make that product durable and light. These products can also be cost-effective. All of this makes glass fiber and materials made with it good for many uses.

Is glass fiber safe to use in residential construction?

Yes, glass fiber is safe to use in homes if you handle it the right way. People often use it in building materials like insulation and reinforced plastic. The fibers can make your skin feel itchy for a short time. But these fibers are not toxic substances. With the right safety steps, they do not cause long-term health problems.

Can glass fiber be recycled or reused effectively?

Yes, glass fiber can be recycled. In the manufacturing process, scrap from glass fiber is often melted again and used to make more products. When it comes to finished composite material, it is harder to recycle, but people are starting to do it more often. Most of the time, ground-up composite material is used to fill up other new materials. These ways of recycling and reusing glass fiber help make it more sustainable.